Revolutionizing Manufacturing with Robo3DPrinter Technology

The advent of 3D printing has been one of the most transformative developments in modern manufacturing. Among the various innovations, the robo3dprinter stands out for its versatility and effectiveness. This article explores the phenomenal impact of robo3dprinter technology on the business landscape, showcasing its advantages, applications, and future prospects.

What is a Robo3DPrinter?

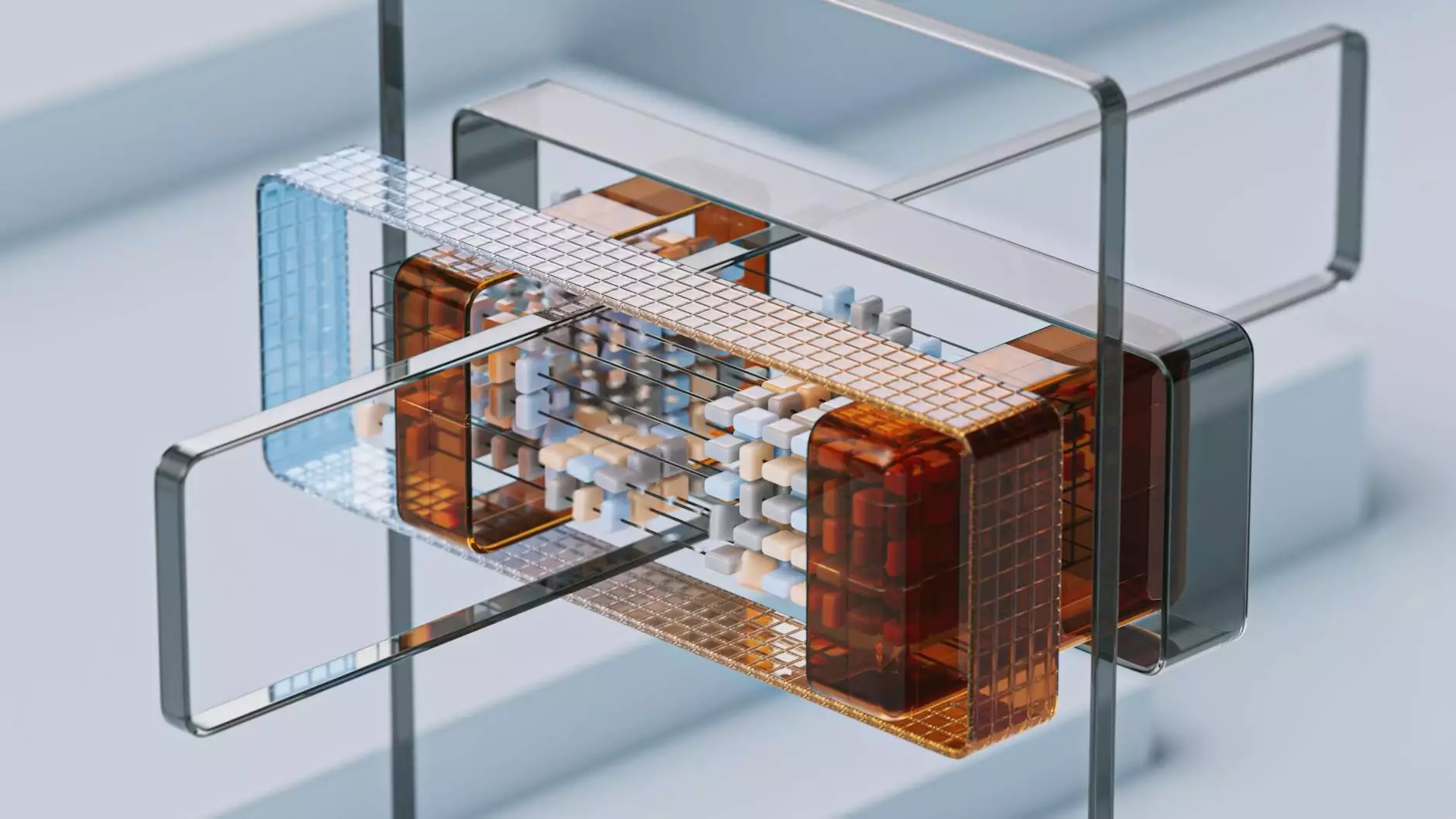

A robo3dprinter is a type of 3D printing machine that utilizes advanced robotics to create three-dimensional objects layer by layer. This technology combines the functionalities of traditional printing with innovative mechanical processes. Unlike conventional printing methods, a robo3dprinter can produce intricate designs and accurately reproduce complex shapes, making it ideal for various industries.

The Science Behind 3D Printing

3D printing, also known as additive manufacturing, involves a series of processes that build objects from a digital file. This innovative technology allows businesses to:

- Reduce Material Waste: Traditional manufacturing methods often involve cutting away excess material, leading to significant waste. In contrast, 3D printing uses only the material necessary to create an object.

- Enhance Design Flexibility: With a robo3dprinter, designers can push the boundaries of creativity, producing complex geometries and customized products that would be challenging or impossible with traditional techniques.

- Speed up Production Times: 3D printing significantly shortens the production cycle. What used to take weeks can now be accomplished in days or even hours.

Applications of Robo3DPrinter Technology

The applications of robo3dprinter technology are vast and growing. Some of the most notable industries benefiting from this innovative printing method include:

1. Aerospace Industry

The aerospace sector is one of the leading adopters of 3D printing technology. Using a robo3dprinter, companies can produce lightweight components that meet stringent safety regulations. The ability to create complex parts reduces the overall weight of aircraft, improving fuel efficiency and performance.

2. Healthcare

In healthcare, robo3dprinters are used to create customized prosthetics, dental implants, and even bio-printed tissues. These printed materials can be tailored to the exact specifications of a patient, enhancing comfort and functionality.

3. Automotive Manufacturing

Automobile manufacturers are incorporating 3D printing to streamline production and offer customization options for consumers. A robo3dprinter can create parts on-demand, reducing inventory costs and improving supply chain efficiency.

4. Education and Research

Educational institutions are using robo3dprinters to teach students the principles of design, engineering, and manufacturing. This hands-on experience prepares students for the future workforce and promotes innovation.

The Benefits of Using Robo3DPrinter Technology in Business

Integrating a robo3dprinter into manufacturing processes presents numerous benefits for businesses:

Cost Efficiency

By minimizing material waste and reducing production time, companies can significantly decrease costs. Additionally, businesses can lower their overhead by reducing the need for large inventory stores.

Rapid Prototyping

Robo3Dprinters allow for the rapid creation of prototypes. This capability is crucial for product development cycles, as it facilitates quick iterations and adjustments based on feedback, ultimately speeding up the time-to-market process.

Customization and Personalization

Today’s consumers are seeking more personalized products. Robo3Dprinter technology empowers businesses to cater to individual preferences, fostering customer satisfaction and loyalty.

Sustainability

With a growing emphasis on sustainable manufacturing, 3D printing is leading the way for environmentally friendly practices. Using less material and generating less waste aligns with the global push towards sustainability.

Challenges and Considerations When Using Robo3DPrinter

While the benefits are significant, businesses must also navigate certain challenges when adopting robo3dprinter technology:

1. Initial Investment Costs

The initial cost of high-quality robo3dprinters can be a barrier for some businesses. However, companies must weigh this against the long-term savings and benefits.

2. Skill Gap

Implementing 3D printing technology requires skilled personnel who understand the technology and design software. Continuous training and education are vital to overcoming this obstacle.

3. Intellectual Property Concerns

With the ability to replicate complex designs, intellectual property rights become crucial in the 3D printing realm. Businesses need to navigate these concerns to avoid legal issues.

The Future of Robo3DPrinter Technology

As technology continues to evolve, the future of robo3dprinter devices seems bright. Emerging trends include:

- Integration with AI: The integration of artificial intelligence in 3D printing processes can optimize designs and streamline production, making the technology even more efficient.

- Advanced Materials: The development of new printing materials, including metals and bio-compatible substances, will expand the possibilities for robor3dprinter applications.

- Decentralized Manufacturing: With 3D printers becoming more accessible, a shift towards localized production could emerge, reducing shipping costs and lead times.

Conclusion

The robo3dprinter is not just a technological innovation; it symbolizes a shift towards more efficient, sustainable, and customizable manufacturing processes. Companies that embrace this technology stand to benefit greatly by reducing costs, enhancing product offerings, and staying ahead of competitors in an ever-evolving market. As we look ahead, the impact of 3D printing technology will only grow – transforming the landscape of industries and creating limitless possibilities for the future of business.

For more information on how to integrate 3D printing into your business strategy, visit 3DPrintWig.com.